This I.P. Engineering model is roughly based upon the O&K MD2 locomotive.

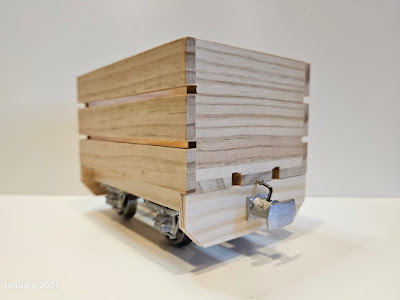

Starting with the sub-frame on which the body will be mounted, buffer beams were added, each with a forty five degree cut across the top corners.

Next the basic rolling chassis was constructed, together with the central gear for the motor.

The kit came with two little screws to mount the two sections together. I may have misunderstood the assembly instructions and couldn't see how they fitted, so I chose to use two small bolts with two threaded nuts. (those used to fit a mains light switch fascia plate).

Putting the two sections aside, a start was made on the body. Starting with the engine housing, rivet detail was added to the front and two side panels (1/16" x 3/8"). As these would be hidden, they were left untrimmed. Once fixed the panels were glued and made square.

The cab was made in a similar way, again using rivet detail. These were glued in, cut to size and filed, with the cut offs kept for later use.

Both the engine housing and the cab were then glued together and checked for square.

Now was a good time to add the wiring from the motor to the battery pack via the three position switch.

With just a few more steps, the body and chassis are prepared for priming. Using the cardboard profiles included, the engine access doors and window trims were glued in place. The cut-offs from the rivets were added to the doors edge to create the appearance of hinges. Bolt heads were glued in place on the buffer beams. And lastly, an angled frame was centrally fitted to the front of the sub-frame. This will assist later when fixing the body to the sub-frame after painting.

Adding weight and motive adhesion, the cast white metal components were fixed in place on the sub-frame with epoxy resin. The body and sub-frame were subsequently primed with Humbrol grey primer.

The chassis was then spray painted with Halfords Acrylic Satin Black and Halfords Acrylic 'Fiat Red Orange' for the buffer beams. More weight was added once the couplings had been primed and painted.

With the couplings added the cab was presented to the body shop for spraying. Once masked off to protect the interior, the body was painted using Halfords Acrylic 'Peugeot Royal Blue'. Three coats later, the body was left to harden for twenty minutes or so before the tape was removed. Loosely fitted to the chassis, all was checked for appearance.

To enable the roof to be removed, just in case cab detailing was later required, the roof was pre-formed using plastic strips to the contour of the cab. An exhaust was added from

SLR Models, secured with two small screws to the bonnet. A drawing pin and bead were used to create an air intake. Primed and painted with Halfords Acrylic Satin Black.

The body was then attached to the chassis using two small black screws fitted into the angled bracket at the front, below the radiator grill. A small block of wood (Jenga) was glued under the seat and then screwed through the chassis into the block.

I selected "Alwin" from Kara's Little Kharacters to be the driver. Painted and fitted onto his lovely soft red plush seat, he was ready to go.

The End.

.webp)