HLR needed a mobile crane for the Maintenance Dept., so Plateway Models were recruited to provide.

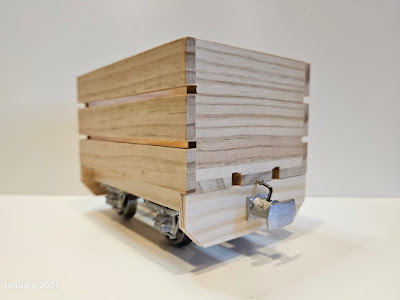

As it required to be mobile, a basic wagon from their fleet was sourced and built accordingly.

Following the instructions carefully the parts for the crane were assembled and tested 'dry'.

Instead of utilising the string/rope provided, a small link chain was used. This added weight and strength to it's lifting power.

Fifteen pennies were added to the counterweight box before it was sealed. This provided weight and balance to the jib.

A part from the wagon floor, all parts were primed Humbrol Grey (1). Final coats for handles Humbrol Bright Red (19), jib ends Humbrol Black (21) and wagon plates and buffer beams Humbrol Black (33).

A coat of Coach & Wagon Satin varnish was then applied to the wagon's body and crane.

Decals were applied before a final coat of the above varnish.

To add more stability and weight, leaded weights were adhered to the underneath of the wagon.

A large fishing lead sinker was fitted to the chain just above the hook. Again this added weight and aided it's operation.